Page 242 - 《环境工程技术学报》2023年第1期

P. 242

· 238 · 环境工程技术学报 第 13 卷

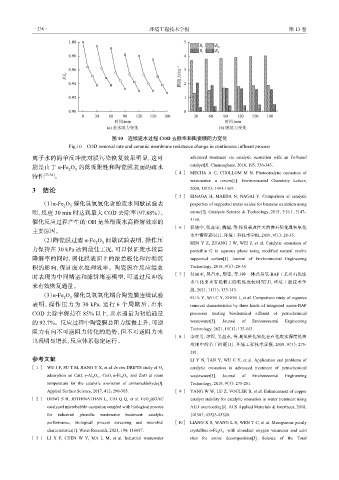

图 10 连续进水过 程 CO 去除率和陶瓷膜阻力变化

D

Fig.10 COD removal rate and ceramic membrane resistance change in continuous influent process

离子水的简单反冲洗对膜污染恢复效果明显,这可 advanced treatment via catalytic ozonation with an Fe-based

能是由 于 α-Fe O 的低吸附性和陶瓷膜表面的疏水 catalyst[J]. Chemosphere,2018,195:336-343.

3

2

特性 [33-34] 。 [ 4 ] MECHA A C, CHOLLOM M N. Photocatalytic ozonation of

wastewater: a review[J]. Environmental Chemistry Letters,

3 结论 2020,18(5):1491-1507.

[ 5 ] EINAGA H, MAEDA N, NAGAI Y. Comparison of catalytic

(1)α-Fe O 催化臭氧氧化含酚废水间歇试验表 properties of supported metal oxides for benzene oxidation using

3

2

明,反 应 30 mi 时达到最 大 CO 去除率(97.88%)。 ozone[J]. Catalysis Science & Technology,2015 ,5 (6 ) :3147-

D

n

催化反应过程产生的·O 是苯酚废水高降解效率的 3158.

H

[ 6 ] 任越中, 张嘉雯, 魏健, 等.铈负载改性天然沸石催化臭氧氧化

主要原因。

水中青霉素G[J]. 环境工程技术学报,2019,9(1):28-35.

(2)陶瓷膜过 滤 α-Fe O 间歇试验表明,操作压

3

2 REN Y Z, ZHANG J W, WEI J, et al. Catalytic ozonation of

力保持 在 30 kP 达到最佳工况,可以保证废水较高 penicillin G in aqueous phase using modified natural zeolite

a

降解率的同时,弱化膜表面上的浓差极化和污垢沉 supported cerium[J]. Journal of Environmental Engineering

积的影响,保证废水处理效率。陶瓷膜在反应结束 Technology,2019,9(1):28-35.

时表现为中间堵塞和滤饼堵塞模型,可通过反冲洗 [ 7 ] 付丽亚, 吴昌永, 周鉴, 等.3种一体式臭氧-BAF工艺对石化废

水生化出水有机物去除特性比较研究[J]. 环境工程技术学

来有效恢复通量。

报,2021,11(1):135-143.

(3)α-Fe O 催化臭氧氧化耦合陶瓷膜连续试验

3

2 FU L Y, WU C Y, ZHOU J, et al. Comparison study of organics

表明,操作压力为 30 kPa,运行 6 个周期后,出水 removal characteristics by three kinds of integrated ozone-BAF

CO 去除率保持 在 85 % 以上,出水通量为初始通量 processes treating biochemical effluent of petrochemical

D

的 92.7%。反应过程中陶瓷膜总阻力缓慢上升,可逆 wastewater[J]. Journal of Environmental Engineering

Technology,2021,11(1):135-143.

阻力有向不可逆阻力转化的趋势,但不可逆阻力未

[ 8 ] 李亚男, 谭煜, 吴昌永, 等.臭氧催化氧化在石化废水深度处理

出现明显增长,反应体系稳定运行。

应用中的若干问题[J]. 环境工程技术学报,2019,9(3):275-

281.

参考文献 LI Y N, TAN Y, WU C Y, et al. Application and problems of

[ 1 ] WU J F, SU T M, JIANG Y X, et al. In situ DRIFTS study of O catalytic ozonation in advanced treatment of petrochemical

3

adsorption on CaO, γ-Al O , CuO, α-Fe O and ZnO at room wastewater[J]. Journal of Environmental Engineering

2

3

3

2

temperature for the catalytic ozonation of cinnamaldehyde[J]. Technology,2019,9(3):275-281.

Applied Surface Science,2017,412:290-305. [ 9 ] YANG W W, LU Z, VOGLER B, et al. Enhancement of copper

[ 2 ] DENG S H, JOTHINATHAN L, CAI Q Q, et al. FeO @GAC catalyst stability for catalytic ozonation in water treatment using

x

catalyzed microbubble ozonation coupled with biological process ALD overcoating[J]. ACS Applied Materials & Interfaces,2018,

for industrial phenolic wastewater treatment: catalytic 10(50):43323-43326.

performance, biological process screening and microbial [10] LIANG X S, WANG L S, WEN T C, et al. Mesoporous poorly

characteristics[J]. Water Research,2021,190:116687. crystalline α-Fe O with abundant oxygen vacancies and acid

2 3

[ 3 ] LI X F, CHEN W Y, MA L M, et al. Industrial wastewater sites for ozone decomposition[J]. Science of the Total